Getting the most out of B.C.’s challenged wood fibre base

The focus of the funding was to be on creating a higher level of wood utilization for wood fibre and wildfire risk reduction. The FESBC project review and approval process clicked smoothly into high gear.

It was early in 2024 when the FESBC announced the cumulative approval of 66 projects valued at $47.9 million. A total of 39 of those projects were led by or involved First Nations.

“We are very proud of the project partners in local areas all over B.C. who have stepped forward with creative and thoughtful projects which not only utilize more waste wood or reduce wildfire risk, but also drive additional benefits,” observed Steve Kozuki, then FESBC’s executive director.

“FESBC projects show that there doesn’t need to be a trade-off between the environment or the economy—it can and should be a win for both,” added Kozuki.

A project in B.C.’s Southern Interior region demonstrates the symbiosis well. The project’s partners are Stuwix Resources, a First Nations-owned and operated fibre management company, and Valley Carriers, a well-established diversified transportation enterprise owned and operated by the Klassen family, based in Abbotsford, B.C.

The initiative for the co-operative venture came from the First Nation peoples involved and was facilitated by the FESBC.

“The community members have made it clear they wanted a better job of utilizing the resources provided by the forests,” summarized Lindsay Tighe, general manager of Stuwix Resources.

The eight First Nations in the Stuwix joint venture are based in and around the Nicola Valley region of the southern interior and include: the Lower Nicola Indian Band; the Coldwater Indian Band; the Nooaitch Indian Band; the Shacken Indian Band; the Upper Nicola Indian Band; the Siska Indian Band and the Upper Similkameen Indian Band. Stuwix manages the bands’ non-replaceable forest licences which have a collective annual cut of around 170,000 cubic metres of primarily lodgepole pine forests, explained Tighe. The plan was to truck the First Nations’ timber to a central location in Merritt. The timber was reviewed there, and sorted and processed into end products and uses.

These ranged from use by the region’s three main licencees—Tolko, Aspen Planers and Weyerhaeuser—to post and rail use, pulp wood and fibre for energy production. The pilot part of the project began in 2023 and involved about 10,000 cubic metres of wood. “We wanted to test our concept operationally,” explained Tighe.

There were positive early indicators that the joint venture was on the right track. For example, shortening post and rail stock to eight foot lengths increased volume by about five per cent, reported Tighe. Clear cutting and moving the tree length volumes to a central location for processing had indicated a potential of 95 per cent of log utilization, he added, in accordance with Stuwix’s wishes.

Valley Carriers, the other principal partner in the venture, began modestly in 1963. Neil Klassen started his own trucking business with a single vehicle and a strong willingness to work. Now, four generations later, the Klassen family remains closely involved with running a business that’s thrived and diversified. Building and maintaining working relationships has become a hallmark of the Klassen business model. It has helped the past slot neatly with the present.

“The vision for this project is to eliminate the forestry residual waste that is normally under-utilized, piled and burned,” pointed out Kate Colman, Klassen’s marketing manager. Instead, the project partners have adopted a more sustainable solution.

“This approach would salvage the stem tops, lower value logs and burnt timber to be used for products such as post and rail, pulp, firewood, pellets, briquettes, sawdust and shavings, wood chips as well as biofuels,” she continued.

On arrival at the Merritt merchandizing site, the tree length log loads are weighed and the utilization process gathers momentum. A Barko 270B hydraulic excavator equipped with a Quadco Southstar 500 processing head was used during the pilot project. The Southstar head’s 360-degree rotation can operate in wood from 18 to 24 inches in diameter.

Supporting the Barko was a Hyundai 3026C forest excavator and a Cat 966C wheel loader.

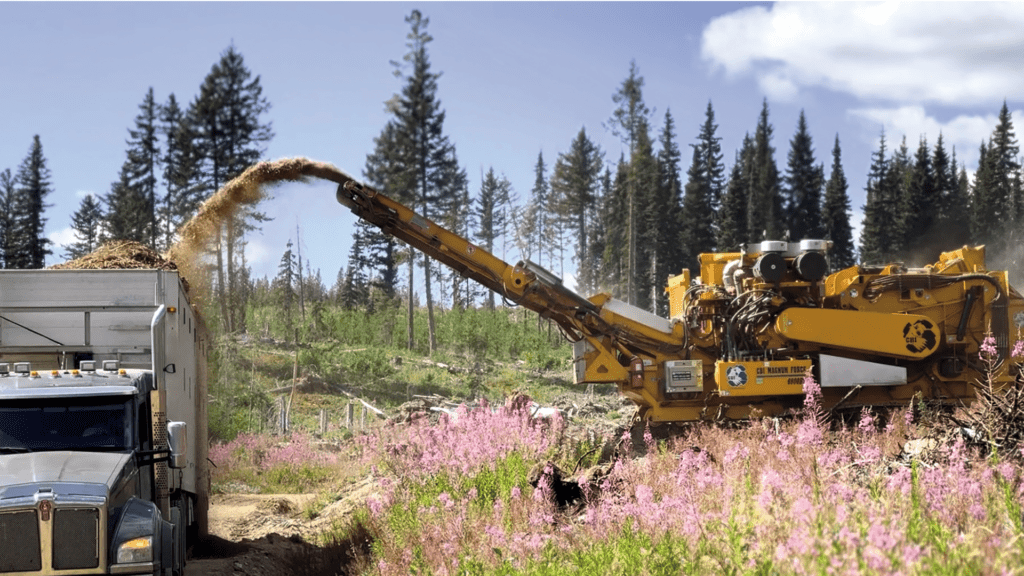

Material unsuited for solid wood product manufacture was processed by a CBI 6800C horizontal grinder with a Keestrack K6 deck screener. Supporting that phase of the operation was a LinkBelt 240 excavator and a Cat 980G wheel loader.

The project’s plan called for trucking the First Nations’ timber to a central location in Merritt. The timber was reviewed there, and sorted and processed into end products and uses. These ranged from use by the region’s main licencees to post and rail use, pulp wood and fibre for energy production. The pilot part of the project began in 2023 and involved about 10,000 cubic metres of wood. The project included funding from the Forest Enterprise Society of B.C. (FESBC).

On the trucking side of the operation were two Western Stars—a tridem drive with a tridem pole trailer and a tridem with a triaxle wagon configuration—and two Peterbilt trucks, a tridem with B-train and a tridem with a hay rack.

The vision for the project is to eliminate the forestry residual waste that is normally under-utilized, piled and burned. Instead, the project partners have adopted a more sustainable solution, to salvage the stem tops, lower-value logs and burnt timber to be used for products such as post and rail, pulp, firewood, pellets, briquettes, sawdust and shavings, wood chips as well as biofuels.

Colman noted that in today’s environment, the wood bioenergy, bioproduct and agriculture sectors all require a creative fibre supply. The forest sector in B.C. is characterized by AAC reductions and mill closures primarily due to the effects of the mountain pine beetle and spruce beetle infestations, wildfires and a reduced land base for timber harvesting.

B.C. harvest levels went from 55 million cubic metres in 2021 to 34 million in 2023, reflecting the much-reduced fibre base.

“These changes are causing supply constraints and increased prices for wood fibre,” observed Colman. More complete wood fibre utilization has rarely been more vital including the elimination of in-bush burning and greenhouse gas emissions.

The last word is from FESBC’s senior manager, Gord Pratt: “Exploring new ways to optimize the delivery and use of forest fibre is long overdue and will only help the economy of the Merritt area.

“Lessons learned here will help other regions of the province, and assist in building a more stable and diverse forest industry which is critical for the future of rural B.C.,” he added.